Dessicated liposome technology improves vaccine stability

Mountain

Valley MD, Ontario, Canada

The results of the first study to evaluate the

stability of Trivalent Inactivated Poliovirus Vaccine (tIPV) formulated in

desiccated liposomes (QuIcksometm) has yielded promising results.

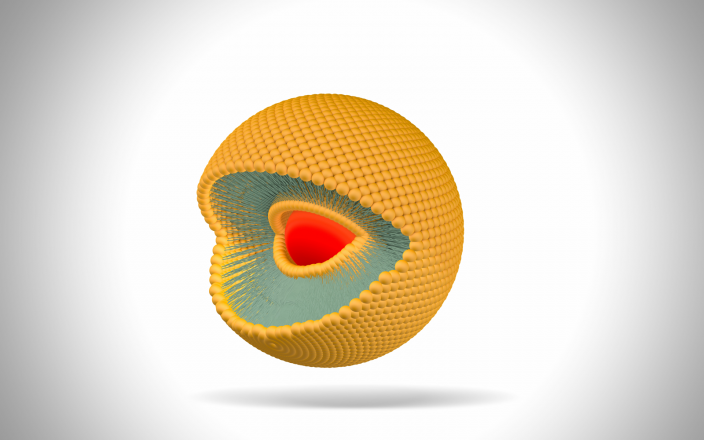

The technique involves laying down a film of desiccated liposomes containing

the vaccine in a vial. The vaccine is the reconstituted using Water for

Injection at the point of administration. Testing the stability of the vaccine at higher

ambient temperatures is important to comply with World Health Organisation

(WHO) Controlled Temperature Chain requirements.

Controlled Temperature Chain (CTC)

The WHO Controlled Temperature Chain allows

vaccines to be kept at temperatures outside the traditional cold chain of +2°C

to +8°C for a limited period of time under monitored and controlled conditions,

as appropriate to the stability of the antigen. A CTC typically involves a

single excursion of the vaccine into ambient temperatures not exceeding a

specified threshold temperature and for a duration of a specific number of

days, just prior to administration.

Controlled cold chain testing results

The

trivalent IPV stability evaluation was conducted to assess the preservation

application of MVMD’s Quicksome™ technology after five days exposure to 40°C.

Trivalent IPV comprises three serotypes of inactivated polioviruses. IPV

serotype two achieved 100% preservation

and stability; IPV serotypes one and three achieved 50% preservation and

stability. The 100% preservation and stability of IPV serotype two exceeds the

World Health Organization’s (WHO) guideline temperature requirements for all

three defined vaccine management categories including traditional cold chain

between +2°C and +8°C, Extended Controlled Temperature Conditions (ECTC) above

+8°C for a specified number of days to support vaccine distribution, and

Controlled Temperature Chain (CTC) where the vaccine must be able to tolerate

ambient temperatures of at least +40°C for a minimum of 3 days.

Previously MVMD has achieved 100% preservation of all three serotypes in a thin film

format up to 30°C.

Dennis Hancock (President &

CEO, Mountain Valley MD) said,

“IPV serotypes one and three will be the focus of

the next phase of evaluation the company will conduct by focusing on lowering

residual moisture content, achieving more robust liposomal protection, and

faster drying of the mixture within the vial.

Our objective is to achieve full CTC compliance at 40°C for tIPV polio

vaccines in a vial format that can be reconstituted at the point of

administration for injection, and we are immediately commencing this work with

the Food and Drug Administration (FDA) Polio Lab under our recently signed

collaborative research agreement.”

Cold chain

challenges and opportunities

Cold chain is a temperature-controlled supply chain

that prescribes necessary conditions during the transport, storage, and

handling of vaccines to preserve a temperature range between +2°C and +8°C from

the time the vaccine is produced until it is administered. Current estimates place cold chain biopharma

logistics spending for 2020 at USD $17.2 billion annually, with costs due to

failures in temperature-controlled logistics estimated at approximately USD $35

billion per year, and in most cases representing over half of a vaccine’s

cost. The WHO estimates that more than

50% of vaccines are wasted globally every year due to temperature control,

logistics and shipment-related issues.

The Quicksome™ technology holds out the possibility of reducing the complexity,

wastage and significant costs associated with cold chain distribution.